Shoulder Screws are an extremely reliable attachment method.

Several standard screws are available, while springs generate the appropriate mounting

force/pressure.

Alpha can design and produce the entire assembly, including the heat sink, shoulder screws,

springs, and thermal interface material.

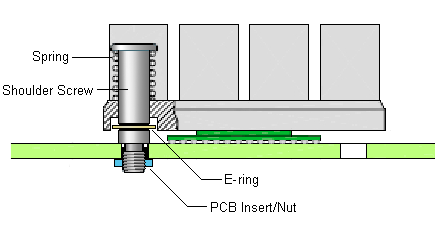

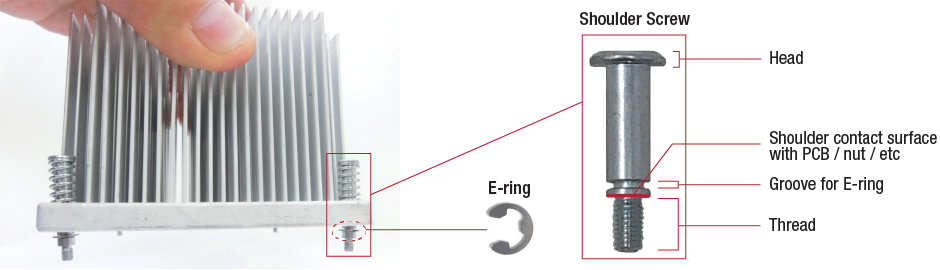

Shoulder screws consist of the "Head", the "Shoulder", and the "Thread" sections.

Within the shoulder section, an E-ring can be inserted into the groove, making the screw captive to the

heat

sink.

Captive hardware allows the heat sink to be easily assembled and disassembled from the PCB without the

inconvenience of loose hardware.

Captive hardware also reduces the total number of components, simplifying the BOM.

The shoulder screws can be used with board mounted threaded inserts or standoffs.

If the treaded inserts are on the backside of the PCB, the shoulder diameter needs to be larger than the

hole in the PCB.

When the shoulder screws are tightened, the shoulder will bottom on the PCB surface or the standoff.

Once the shoulder makes contact, the heat sink is properly installed.

Shoulder screws offer the most reliable and rugged attachment method possible. Passed all shock and vibration testing.

Captive hardware and simple installation minimizes possibility of error and damage.

A standard or custom backing plate is an option for high attachment forces.

Hole location and attachment forces can be customized for each specific application.

Appropriate attachment force/pressure can be consistently generated through screw/spring selection.

High performance interface materials including phase change and thermal grease can be used instead of tape or epoxy.

Please visit Spring Selection page.

As discussed above, there are several different hardware components that can be used to attach shoulder

screw heat sinks to the PCB.

Final heat sink design will depend on which mounting component is used.

Please review the specification of each mounting component and how the component is used to attach the

heat

sink to the PCB.

Alpha's standard shoulder screw thread specification is M3. If you need additional information regarding

these components, please contact Alpha sales.

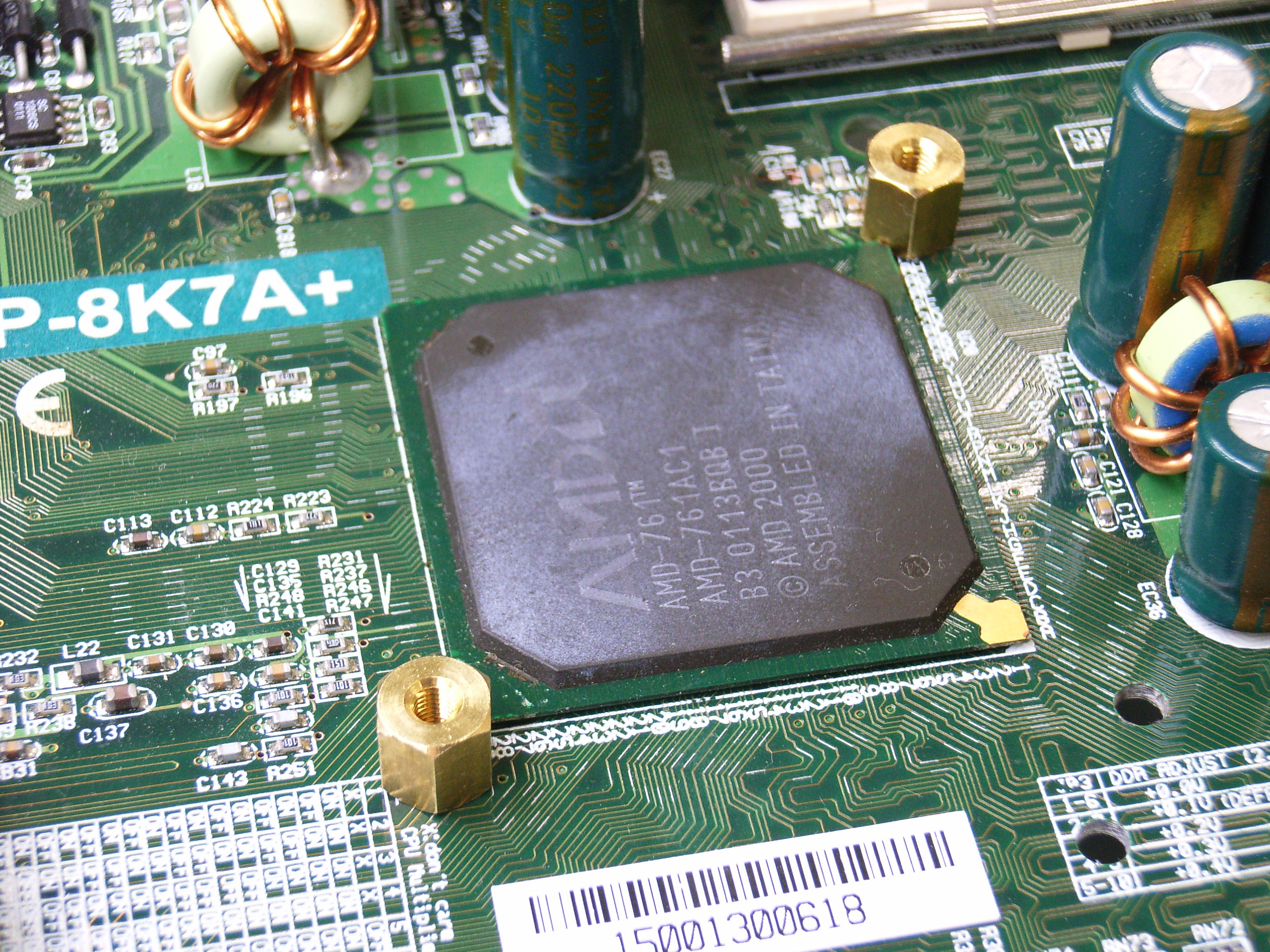

Press-in or Soldered Inserts and Spacers *

Nuts

Stand-offs

Backing Plate

Installed on PCB surface (component side).

Nut required on backside of PCB.

Backing plate is installed on the backside of the PCB. It provides attachment hardware and additional stiffness, preventing excessive bowing of the PCB. Alpha's standard backing plates.

*Alpha does not provide these components as standard parts.

Typical attachment methods

Test Report (Shock and Vibration)

© 2019-2025 Alpha Novatech, Inc.