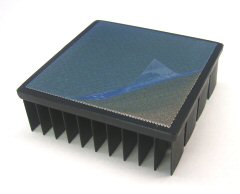

All of our standard series heat sinks can be ordered with pre-applied thermally conductive adhesive tapes. Alpha keeps several types of tape in stock, ready for immediate application and shipment.

- Simple and Easy attachment

- Short lead-time (Typically, we will have the tape in stock)

- Low cost

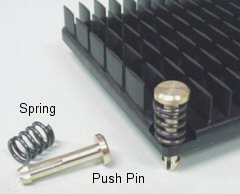

The Heat Sink is attached to the board by pushpin. The spring load applies appropriate pressure to the chip. Several standard sizes of pushpins are available. We can provide the total design, including springs, pushpins and thermal interface material.

- Applies appropriate compressive load to BGA solder balls instead of tension or shear

- Superior thermal performance, a Phase Change Material or thermal grease can be used as the thermal interface material

- Re-workable

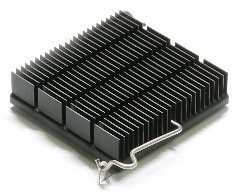

Heat Sink is secured to the PCB by Z-shape clip and anchors. The anchors are mechanically mounted to the PCB by snap-in or soldering. We offer multiple standard Z-shape clips and anchors to accommodate various board layouts and PCB thicknesses. We can provide a complete assembly, including the heat sink, Z-shape clip, and thermal interface material. The anchors are mounted separately at the board level.

- Superior thermal performance, a Phase Change Material or thermal grease can be used.

- Re-workable

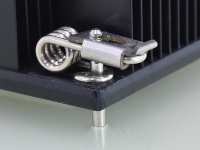

Similar to Quick Set, but features a non-captive loose clip, allowing greater application flexibility. Various CQZ & QSZ clips, and anchor pin lengths are standardized and can be used with many of our standard catalog heatsinks, AS-IS. If a custom layout is required, new clips can be quickly designed and produced. Mounting pins only require 1.5mm diameter holes (CQZ) and 1.8mm (QSZ) in the PCB. The small footprint greatly reduces the amount of PCB space sacrificed for heat sink attachment, minimizing or eliminating the need to move board traces.

- Interface materials with superior thermal performance like phase change or grease can be used.

- Re-workable

Mounting pins only require 1.8mm[.071"] diameter holes in the PCB. Small footprint greatly reduces the amount of PCB space sacrificed for heat sink attachment, minimizing or eliminating the need to move board traces.

- Small PCB Area

- Stable & Robust

- Location and Orientation Guide

- Pre-Assembled

- Easy-Install

- Adjustable Attachment Force

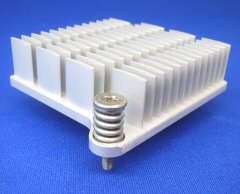

The Heat Sink is attached to the board with shoulder screws. The spring load applies the appropriate pressure to the chip. Several standard sizes of screws are available. We can provide the total design, including springs, screws and thermal interface material.

- Applies appropriate compressive load to BGA solder balls instead of tension or shear

- Superior thermal performance, a Phase Change Material or thermal grease can be used as the thermal interface material

- Re-workable

In situations where relatively massive heat sinks are used, additional mounting methods may be required. This can include the use of backing plates or standoffs to act as attachment points for screws. Please contact our support personnel regarding the use of such items and the corresponding hardware.

Please contact Alpha sales for more details.

© 2007-2022 Alpha Novatech, Inc.