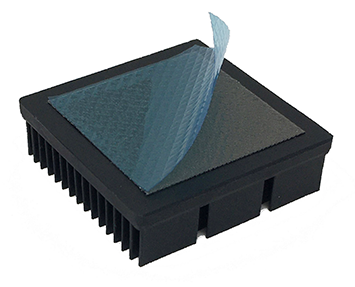

Thermally conductive adhesive tapes are widely used as a simple and effective method of heat sink attachment. Alpha offers several different adhesive tapes in multiple sizes. Tape choice will depend on device material, contact area size, flatness, thermal performance, etc....

| T412 | T411 | 8810 | 8815 | BP105 | |

|---|---|---|---|---|---|

|

|

|

|

|

|

| Manufacturer | Parker | Parker | 3M | 3M | Henkel |

| Data Sheet | #T412 | #T411 | #8810 | #8815 | #Bond-Ply TBP 850 |

| Color | Gray | Clear (Silver) | White | White | White |

| Base | Acrylic | Silicone | Acrylic | Acrylic | Acrylic |

| Operating Temperature (degC) | -30 to +125 | -50 to +150 | — | — | -30 to +120 |

| Dielectric Strength | — | — | 668 Volts / mil | 668 Volts / mil | 3000 Vac |

| Thickness | 0.23mm [.009"] | 0.25mm [.010"] | 0.25mm [.010"] | 0.375mm [.015"] | 0.127mm [.005"] |

| Attachment | Ceramic Metal |

Ceramic Metal Plastic |

Ceramic Metal Plastic |

Ceramic Metal Plastic |

Ceramic Metal Plastic |

| Thermal Impedance (degC-in2/W) |

0.30 (@300PSI) | 1.0 (@300PSI) | 0.90 | 1.20 | 0.52 |

| Thermal Conductivity (W/mK) | 1.40 | 0.5 | 0.60 | 0.60 | 0.8 |

| UL | — | 94V-0 | 746A, 746C | 746A, 746C | 94V-0 |

|

Model Name:

T412

{{MODELNAME['T412']}}

|

Model Name:

T411

{{MODELNAME['T411']}}

|

Model Name:

8810

{{MODELNAME['8810']}}

|

Model Name:

8815

{{MODELNAME['8815']}}

|

Model Name:

BP105

{{MODELNAME['BP105']}}

|

The shear strength of an adhesive tape is dependent on many factors, including contact area size, flatness, and preparation of the contact surface. The application instructions from the tape manufacturer must be followed to ensure proper adhesion. Please refer to the Data Sheet from each tape manufacturer for detailed instrucitons.

The thermal performance of tape can be good, but high performance TIMs such as phase change material or thermal grease offer much lower thermal impedance. For applicaitons with high power dissipation and small contact area size, the use of thermal tape would not be appropriate. Please refer to the Specification and Data Sheet for performance details.

There are several thermally conductive tape vendors, each offering multiple tape versions. Although each vendor publishes its own product test data, the results are highly dependent on the test methods employed, and the test environment. Test conditions can be quite different from real world operating conditions, making it difficult to accuratey compare tapes. In light of this, we tested the thermal performance of the tapes we offer in our catalog in our thermal lab. These results offer a good reference for comparison purposes.

Adhesive Tape Comparison Data Details

- Standard Tape Size

| Type | Square Tape Size (mm) | Sheet Tape Size (mm) |

|---|---|---|

| T412 | 10, 14, 17, 20, 23, 25, 28, 30, 32, 35, 38, 40, 42, 45, 48, 50, 58 |

190 x 300 |

| T411 | 150 x 300 | |

| 8810 | 177 x 300 | |

| 8815 | 177 x 300 | |

| BP105 | 150 x 300 |

Choose a piece of tape that is large enough to completely cover the contact area plus an additional 1.5mm in each direction. The extra material ensures that the tape will cover the package contact area if it the heat sink not perfectly centered. Additionally, if the package size is close to the size of the heat sink, leave about 1mm of space between the edge of the heat sink and the tape. For example, if a 40mm heatsink is used on a 40mm package, the proper tape size would be 38mm.

Note

If the chip or package's surface is slightly concave, we recommend the use of tape that is slightly smaller than the chip's contact area (approximately 85%). This ensures that the tape will only be in contact with the center (hot spot) of the chip/package. The worst case scenario would be a concave package, where only the outer perimeter of the package is in contact with the heat sink. Another option for a non-flat/concave package would be the choice of 3M 8815 tape. The 3M 8815 tape is thicker and will conform to a concave surface better than the thinner, less compliant tapes.

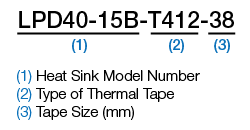

We have created an intuitive system to quickly come up with a part number that can be ordered immediatey.

Example: LPD40-15B-T412-38

Steps

-

Choose the heat sink model number that is appropriate for your

application from our on-line catalog. - Choose the proper type of thermal tape.

- Choose the correct tape size.

-

Create a part name by combining the heat sink model number along

with the tape type and size.

Once the heat sink/tape choice and part number are chosen, please contact Alpha Sales for a quote. Standard series heat sinks and tape are carried in stock. In most cases, samples and initial order quantities can be shipped same day.

Thermal Interface Material

Test Report (Shock and Vibration)

Back to Top

Contact | © 2008 Alpha Company Ltd.