Online Catalog

Index

The length of the current password is short.

Please click here and update your password.

Please click here and update your password.

The current password is invalid.

If you forgot your passward, please click here and update your password.

If you forgot your passward, please click here and update your password.

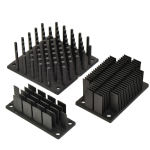

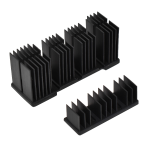

Heat Sink

Accessories

Technical Information

Inquiries | © 2019 Alpha Company Ltd.