Z-shape clips & anchors are a popular mechanical attachment option.

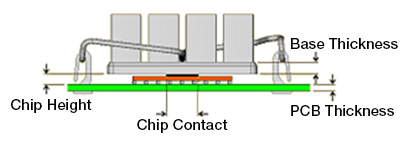

Anchors are mounted to the PCB, and the Z-shape clip secures the heat sink to the anchors while generating the attachment force and pressure. PCB thickness, device height, and anchor spacing will vary for each application. Review the following in order to select the most appropriate Z-shape clip, anchor, and heat sink combination.

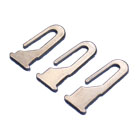

EZ clip

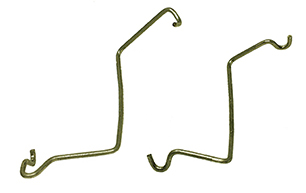

Z-clip

Solderless Anchor

Solder Anchor

Installation image

INDEX

| 1. Z-shape Clip Specification | 4. Clip Load |

| 2. Anchor Specification | 5. Custom Clip Design Request |

| 3. Pairing table with Standard Heat Sinks | 6. Related Links |

We offer two basic types of Z-shape clips:

EZ clip

Shape allows for Easier installation/Toolless. No twisting of the heatsink is required for installation. This will prevent/minimize any possible damage to the device or interface material.

Z-clip

Traditional Z-shape clip. Installation typically requires slight twisting of the heat sink.

| Model | Anchor Pitch X x Y (mm) |

Download | Availability / Price / Order | ||

|---|---|---|---|---|---|

| Data Sheet | Others | ||||

|

EZ-clip

|

30 x 15 |  |

|

|

|

| 40 x 25 |  |

||||

| 50 x 35 |  |

||||

| 60 x 45 |  |

||||

| 70 x 55 |  |

||||

|

30 x 15 |  |

|||

| 40 x 25 |  |

||||

| 50 x 35 |  |

||||

| 60 x 45 |  |

||||

| 70 x 55 |  |

||||

* When selecting the appropriate anchor, please consider the clip attchment load for your heat source.

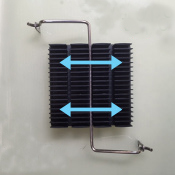

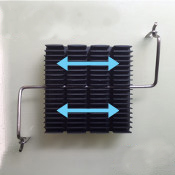

V (vertical) type

AIR FLOW

H (horizontal) type

AIR FLOW

Regarding pairing with standard heat sinks, please refer to the following paring table.

- Please consult Selecting a heat sink to determine if the heat sink will meet the thermal requirements.

- In some cases, the clip may not be able to contact the exact center of a particular heat sink. This will depend on the fin pattern, air direction, and other factors.

- Please check for fit and ease of attachment when using one of these wire clips. In some cases, installation can be difficult, requiring a twisting motion to install the clip and heat sink.

- This table displays heat sink and Z-shape clip pairings based on the direction of clip attachment. With the V type (right above photo), the Z-shape clip runs perpendicular (opposite) of airflow/fin direction. The H type (right bottom photo) runs parallel (inline) with the airflow/fin direction. Please refer to the photos and check the airflow direction prior to pairing selection.

The meaning of each Symbol

| Symbol | Description |

|---|---|

| OK | Z-shape clip can be assembled at the center of heat sink. |

| △ | Z-shape clip can NOT be assembled at the center of heat sink. We do not recommend this attachment in the case of a "V" type. The clip pressure point would be too far from center. |

| Blank | Z-shape clip can NOT be used at all. |

| * | Due to installation difficulty, we do not recommend the use of Z-shape clips with these series of heat sinks if they are taller than 15mm. |

| ** | The heat sink may interfere with the solder anchors. The heat sink will NOT interfere with the solderless anchors. |

Please click part number for detail information such as specification, performance data.

| EZ clip | Z-clip | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

EZR-30x15 EZL-30x15 |

EZR-40x25 EZL-40x25 |

EZR-50x35 EZL-50x35 |

EZR-60x45 EZL-60x45 |

EZR-70x55 EZL-70x55 |

35.5x48.2 35.5Rx48.2 |

44.9x53.5 44.9Rx53.5 |

48.2x60.9 48.2Rx60.9 |

55.8x60.9 55.8Rx60.9 |

47.5x76.2 47.5Rx76.2 |

|||||||||||

| V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | |

| LPD15 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK |

| LPD17 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK |

| LPD19 | OK | △ | OK | △ | △ | △ | △ | △ | △ | △ | △ | △ | ||||||||

| LPD22 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||

| LPD25 | △ | △ | △ | △ | △ | △ | △ | △ | △ | |||||||||||

| LPD28 | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | ||

| LPD30 | OK | OK | OK | OK | OK | OK | OK | OK | OK | |||||||||||

| LPD32 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||

| LPD35 | △ | △ | △ | △ | △ | △ | △ | △ | ||||||||||||

| LPD38 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||

| LPD40 | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||||||

| LPD42 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||

| LPD45 | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | ||||||||

| LPD50 | OK | OK | OK | OK | OK | |||||||||||||||

| LPD52 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||||

| LPD54 | △ | △ | ||||||||||||||||||

| LPD60 | OK | OK | OK | OK | ||||||||||||||||

| LPD2030 | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | ||

| LPD2040 | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | ||||

| LPD3020 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | |

| LPD3040 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||

| LPD3550 | OK | △ | OK | △ | OK | OK | OK | △ | OK | △ | OK | △ | ||||||||

| LPD4020 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | |

| LPD4030 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | |||

| LPD4060 | OK | OK | OK | OK | OK | OK | OK | |||||||||||||

| LPD5035 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||

| LPD5070 | OK | OK | ||||||||||||||||||

| LPD6040 | OK | OK | OK | OK | OK | OK | OK | |||||||||||||

| LPD7050 | OK | OK | ||||||||||||||||||

| MD30 | OK | OK | OK | OK | OK | OK | OK | OK | OK | |||||||||||

| MD35 | △ | △ | △ | △ | △ | △ | △ | △ | ||||||||||||

| MD40 | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||||||

| MD45 | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | ||||||||

| MD50 | △ | △ | △ | △ | △ | |||||||||||||||

| MD54 | OK | OK | ||||||||||||||||||

| MD60 | OK | △** | OK | △ | ||||||||||||||||

| MD4050 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | |||||||

| ULP50 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||||

| ULP60 | OK | OK | OK | OK | ||||||||||||||||

| W15 | OK | △ | OK | △ | △ | △ | △ | △ | △ | △ | △ | △ | ||||||||

| W30 | OK | OK | OK | OK | OK | OK | OK | OK | OK | |||||||||||

| W35 | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||||||

| W40 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||

| W45 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||

| W48 | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | ||||||||||

| W54 | △ | △ | ||||||||||||||||||

| W60 | △** | △ | ||||||||||||||||||

| TL19 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||||

| TL25 | OK | OK | OK | OK | OK | OK | OK | OK | OK | |||||||||||

| TL30 | OK | OK | OK | OK | OK | OK | OK | OK | OK | |||||||||||

| TL35 | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||||||

| TL40 | △ | △ | △ | △ | △ | △ | △ | △ | ||||||||||||

| EZ clip | Z-clip | |||||||||||||||||||

| EZR-30x15 EZL-30x15 |

EZR-40x25 EZL-40x25 |

EZR-50x35 EZL-50x35 |

EZR-60x45 EZL-60x45 |

EZR-70x55 EZL-70x55 |

35.5x48.2 35.5Rx48.2 |

44.9x53.5 44.9Rx53.5 |

48.2x60.9 48.2Rx60.9 |

55.8x60.9 55.8Rx60.9 |

47.5x76.2 47.5Rx76.2 |

|||||||||||

| V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | |

| UB series | We can offer the equivalent UBZ series heatsinks, designed specifically for use with clips in both vertical and horizontal directions, in the exact center. | |||||||||||||||||||

| UB10 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||||

| UB15 | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ |

| UB17 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK |

| UB19 | OK | △ | OK | △ | △ | △ | △ | △ | △ | △ | △ | △ | ||||||||

| UB22 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||

| UB25 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||||

| UB28 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||

| UB30 | OK | OK | OK | OK | OK | OK | OK | OK | OK | |||||||||||

| UB32 | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | ||||

| UB35 | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||||||

| UB38 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||

| UB40 | △ | △ | △ | △ | △ | △ | △ | △ | ||||||||||||

| UB42 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||

| UB45 | △ | △ | △ | △ | △ | △ | ||||||||||||||

| UB48 | OK | OK | OK | OK | OK | |||||||||||||||

| UB50 | △ | △ | △ | △ | △ | |||||||||||||||

| UB52 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||||

| UB54 | △ | △ | ||||||||||||||||||

| UB60 | △** | △ | ||||||||||||||||||

| UB2010 | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | ||||||||||

| UB2030 | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | ||

| UB2035 | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | ||||

| UB2040 | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | OK | △ | ||||

| UB3020 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||

| UB3040 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||

| UB3550 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | |||||||

| UB4020 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||

| UB4030 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||

| UB4060 | OK | OK | OK | OK | OK | OK | OK | |||||||||||||

| UB5035 | OK | OK | △ | OK | △ | △ | OK | △ | OK | △ | OK | △ | OK | △ | ||||||

| UB5070 | OK | OK | ||||||||||||||||||

| UB6040 | OK | OK | OK | OK | OK | OK | OK | |||||||||||||

| UB7050 | OK | OK | ||||||||||||||||||

| UBC60 | △** | △ | ||||||||||||||||||

| UBZ40 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||

| UBZ45 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||

| UBZ50 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||||

| UBZ54 | OK | OK | OK | OK | ||||||||||||||||

| UBZ60 | OK | OK | OK | OK | ||||||||||||||||

| Z series |

Z-shape clip can NOT be used for Z series, except Z19. We can offer the equivalent ZZ series heatsinks, designed specifically for use with clips in both verticaland horizontal directions, in the exact center. |

|||||||||||||||||||

| Z19 | OK | OK | ||||||||||||||||||

| ZZ40 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||

| ZZ45 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||

| ZZ50 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||||

| ZZ54 | OK | OK | OK | OK | ||||||||||||||||

| ZZ60 | OK | OK | OK | OK | ||||||||||||||||

| T series | Z-shape clip can not be used for T series. | |||||||||||||||||||

| N19 | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ |

| N25 | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | ||

| N30 | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | ||

| N35 | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | ||||

| N40 | △** | △** | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | ||||

| N45 | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | ||||||||

| N50 | △** | △** | △ | △ | △ | △ | △ | △ | △ | △ | ||||||||||

| N54 | △ | △ | △ | △ | ||||||||||||||||

| N60 | △** | △** | △ | △ | ||||||||||||||||

| CS40 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||

| CS45 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||

| S1510 | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ |

| S1515 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK |

| S1519 | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ |

| S1525 | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | ||

| S1530 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||

| S1535 | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | ||||

| S1540 | △** | △** | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | ||||

| S1545 | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | ||||||||

| S1550 | OK | OK | OK | OK | OK | OK | OK | OK | OK | OK | ||||||||||

| S1555 | △ | △ | △ | △ | ||||||||||||||||

| S1560 | OK | OK | OK | OK | ||||||||||||||||

| ST15 | △ | △ | △ | △ | ||||||||||||||||

| ST19 | △ | △ | △ | △ | ||||||||||||||||

| ST25 | △ | △ | ||||||||||||||||||

| ST30 | △ | △ | ||||||||||||||||||

| ST35 | ||||||||||||||||||||

| ST40 | ||||||||||||||||||||

| ST60 | ||||||||||||||||||||

| V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | |

| EZR-30x15 EZL-30x15 |

EZR-40x25 EZL-40x25 |

EZR-50x35 EZL-50x35 |

EZR-60x45 EZL-60x45 |

EZR-70x55 EZL-70x55 |

35.5x48.2 35.5Rx48.2 |

44.9x53.5 44.9Rx53.5 |

48.2x60.9 48.2Rx60.9 |

55.8x60.9 55.8Rx60.9 |

47.5x76.2 47.5Rx76.2 |

|||||||||||

| EZ clip | Z-clip | |||||||||||||||||||

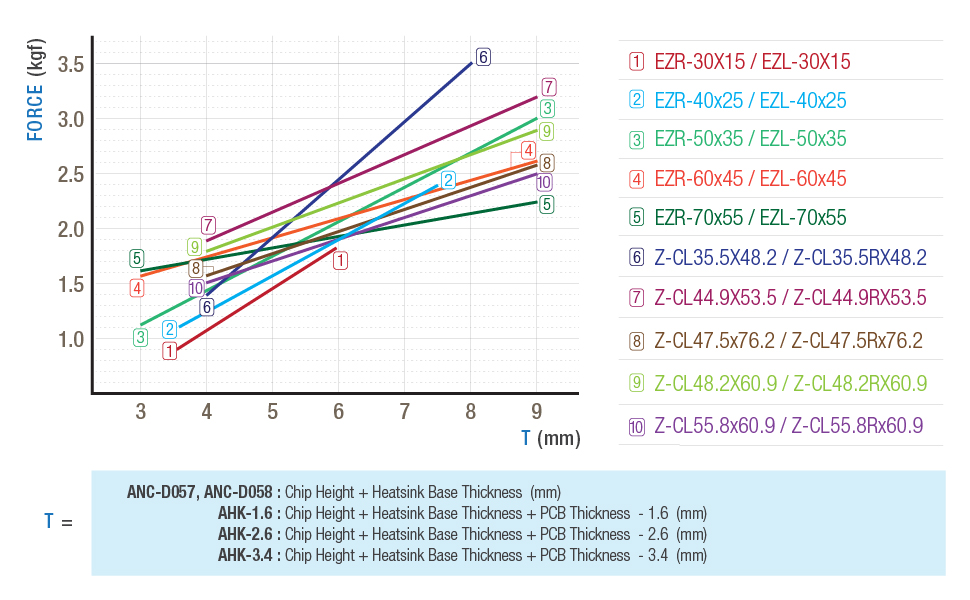

The clip load on the heat source can be calculated by the following tool. Please note that this data is just for reference. Unknown dimensions and tolerances can significantly affect the load on the heat source.

1st, Calculate X value for the graph below based on the formula provided

below the graph.

2nd, Y value (Clip load) can be found from the intersection of "X value"

and "Z-shape clip performance line".

A custom clip can be created if a standard clip will not work with your application.

Please contact Alpha Sales for details.

- Cost & Lead time Information :

- Prototype cost is approximately $300. No NRE/Tooling fee is required.

- Prototype lead time is approximately 2 weeks. Production lead time is 2-4 weeks.

© 2007 Alpha Novatech, Inc.