Online Catalog

Accessory - Thermal Interface Material

Please click here and update your password.

If you forgot your passward, please click here and update your password.

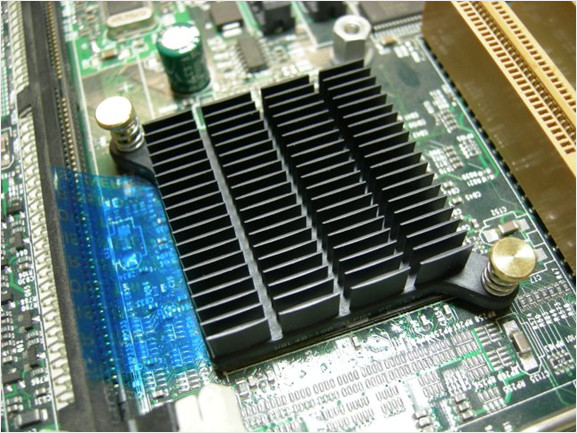

Thermal interface materials fill in any gaps and imperfections in the heat sink base and heat source. This minimizes the interface thermal resistance. Alpha offers several thermal interface materials in various sizes. Material choice will depend on attachment method, contact area size, flatness, attachment pressure, and desired thermal performance.

These materials begin to soften and flow at an elevated temperature, filling the microscopic imperfections between the heat sink and heat source, reducing the thermal interface resistance.

Note : Alpha handles other materials which are not listed below. For example, Parker/Chomerics T766 can be specified. Please contact us if you require a different material.

| Manufacturer and datasheet | Color | Operating Temperature (degC) | Thermal Impedance (degC-cm2/W) | Thickness | Thermal Conductivity | Specific Gravity | |

|---|---|---|---|---|---|---|---|

TPCM5125  | Laird Technologies #Tpcm 5125 | Gray | -40 to +125 | 0.20 (@10psi) | 0.125(mm) [.005"] | 5.3 W/mK | 2.60 |

TPCM5125 | TPCM5125-EB (Eighth Brick) | ||||||

TPCM7125  | Laird Technologies #Tpcm 7125 | Gray | -40 to +125 | 0.10 (@10psi) | 0.125(mm) [.005"] | 7.5 W/mK | 2.50 |

TPCM7125 | TPCM7125-EB (Eighth Brick) | ||||||

These materials are soft and compliant, allowing them to fill any large gaps between the heat sink and heat source. Gap fillers can also be used when a single heat sink is cooling multiple heat sources.

Note : Alpha handles other materials which are not listed below. For example, Laird Tflex HD90000, can be specified. Please contact us if you require a different material.

| Manufacturer and datasheet | Color | Operating Temperature (degC) | Thermal Impedance (degC-in2/W) | Thickness | Thermal Conductivity | Specific Gravity | |

|---|---|---|---|---|---|---|---|

SF10-1  | Laird Technologies #SF10 | Grey | -40 to +125 | 0.04 (@30psi) | 1.00(mm) [.040"] | 10 W/mK | 3.70 |

SF10-1 | |||||||

T-FLEX640  | Laird Technologies #TFlex 640 | Blue-Violet | -45 to +200 | 0.85 (@30psi) | 1.00(mm) [.040"] | 3 W/mK | 1.30 |

T-FLEX640 | |||||||

T-PLI210  | Laird Technologies #Tpli 210A1FG | Rose | -45 to +200 | 0.15 (@30psi) | 0.25(mm) [.010"] | 6 W/mK | 1.40 |

T-PLI210 | T-PLI210-EB (Eighth Brick) | ||||||

T-PLI220  | Laird Technologies #Tpli 220A1 | Blue | -45 to +200 | 0.25 (@30psi) | 0.50(mm) [.020"] | 6 W/mK | 1.40 |

T-PLI220 | |||||||

Thermally conductive grease offers low thermal resistance, and is far less sensitive to mounting pressure than other thermal interface materials.

| Manufacturer and datasheet | Color | Operating Temperature (degC) | Thermal Conductivity | Specific Gravity | Weight | |

|---|---|---|---|---|---|---|

G751-1  | Shin-Etsu Chemical #G751 | Gray | -50 to +120 | 4.5 W/mK | 2.5 | 1 g |

There are many types of thermal interface materials available in the market. Although each vendor publishes its own product test data, the results depend on the test methods and environment. These factors can be very different from real world operating conditions, making it difficult to compare TIMs accurately. In light of this, we tested the performance of the TIMs we offer in our own thermal lab. These results offer a good reference for comparison purposes.

Alpha has standardized the Pull-Tab liner option for phase change material (PCM), TPCM5125 and TPCM7125. If a pre-applied PCM is specified on a heat sink that is 70x70mm or smaller, a pull-tab liner can be added. After selecting TPCM5125 / TPCM7125 as part of a heatsink assembly, the "Add Pull-tab" option will allow the addition of the Pull-Tab liner at a minimum cost increase.

Advantage of pull-tab liner

The Pull-Tab makes removal of the protective liner simpler and quicker, reducing the possibility of the interface material being damaged during the liner removal process. The extended Pull-Tab will also overhang the edge of the heat sink, acting as a visual cue. If the liner is left on by the operator, the pull tab will act as an alert that rework is required before the system can be powered up. With a standard liner, there would be no visual cue if the liner is left on by mistake.

Alpha can create a custom piece of thermal interface material.

Please include the following information in a detailed email request to Alpha Sales (Please include a drawing/sketch, if one is available):

- Company name :

- Contact name :

- Country :

- Tel :

- Estimated quantity :

- TIM part number you would like to customize :

- Customization details/dimensions :

Contact | © 2024 Alpha Company Ltd.