If our standard series heat sinks do not meet your requirements, we can create custom heat sinks at a reasonable cost and lead-time. Please review the following guidelines for custom heat sinks.

There are two major custom design levels.

- Typically, most modifications can be done without the need to create new tooling. Our standard catalog part drawings (2D/3D) can be downloaded from our web site and modified. Please feel free to contact us if you need assistance with this process.

-

Custom tooling is warranted when there is no way to create the desired features from a standard heat sink. This could include fin pattern or base geometry. Tooling would also be warranted if a part is being used in high enough quantity to see a reduction in the production cost. Once a part is tooled, secondary machine work as well as wasted material is minimized.

Alpha will maintain the tooling for the life of production at no added cost. Also, many different heat sinks can be made from one tooling, for example, the base thickness and overall height can be adjusted without having to modify the tooling. Please visit Heat Sink Design for MicroForging® for details.

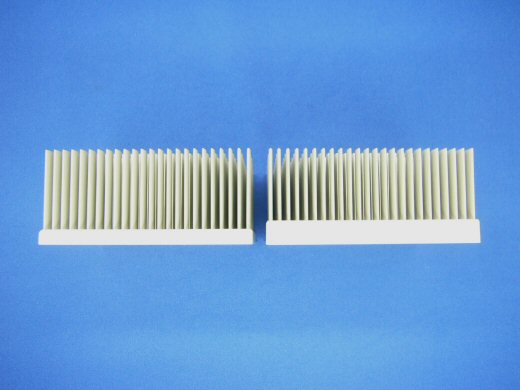

Left:Standard Model W100-45W (Base thickness 7mm, Fin height 38mm)

Right: Customized (Base thickness 11, Fin height 34mm)

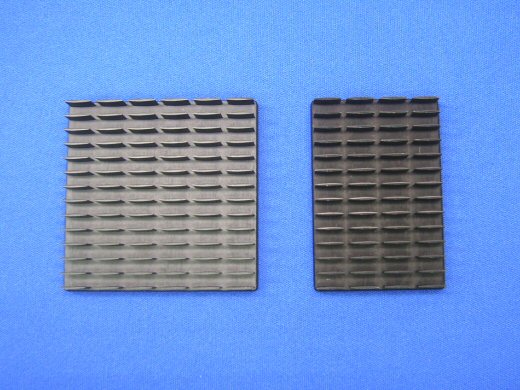

Left:Standard Model LPD60-10B (60x60x10mm)

Right: Customized base size (60x40x10mm)

* Fins would need to be removed if the base cut line crosses fins, or wire-EDM machining would be required.

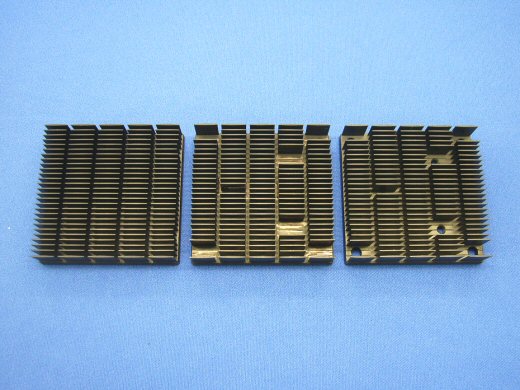

Left:Standard Model UB60-10B

Middle: Heat Sink with fin removal

Right: Heat Sink with fin removal and mounting holes

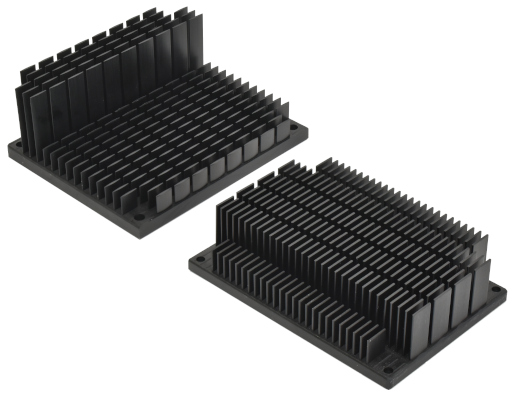

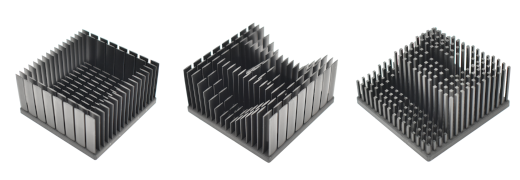

It is possible to create a heat sink with multiple fin heights to deal with clearance issues. We can offer this feature as a step cut.

By using this process, standard heat sinks can be joined together to create larger sizes. This allows customers to obtain custom sizes with short lead times and small MOQs. In addition, by combining products with different fin patterns, optimal performance with regards to thermal resistance and pressure drop can be obtained.

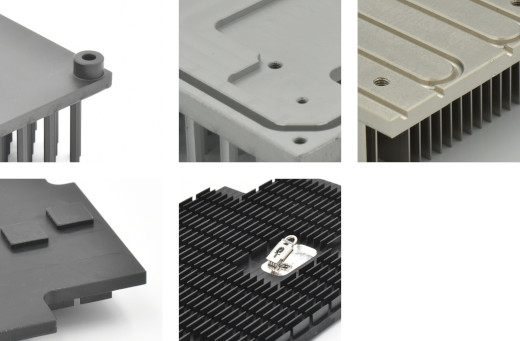

Above left: Boss/Standoff

Above middle: Concave Pocket + Groove

Above right: Groove + Nickel Plating

Lower left: Step/Pedestal + Notch

Bottom center: Post Processing Anodization + Pocket with torsion spring assembly

Various features and shapes such as standoffs, grooves, pockets, pedestals, and notches can be created by secondary machining.

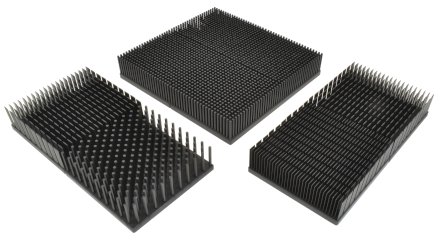

Left:Standard Model LPD40-30B

Right: Customized ( Heat Sink with through holes)

* Note if interference with fins exists, the fins around the holes will be removed.

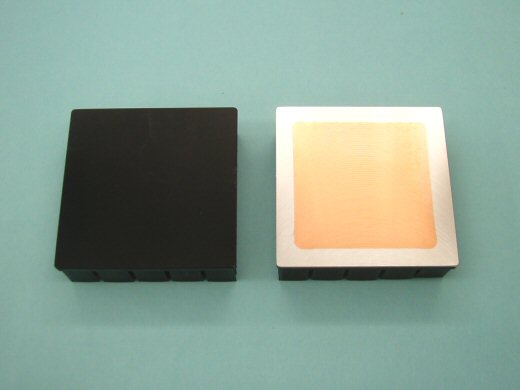

We can embed our heat sinks with a copper plate(heat spreader). The copper has a higher thermal conductivity, reducing spreading resistnace and increasing peformance.

Left: All aluminum Heat Sink

Right: Aluminum Heat Sink with a copper embedded base.

* The copper embedded surface cannot be anodized.

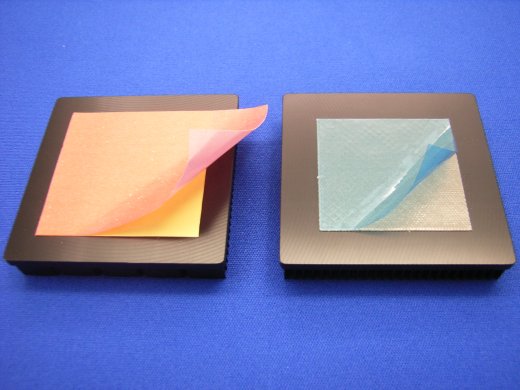

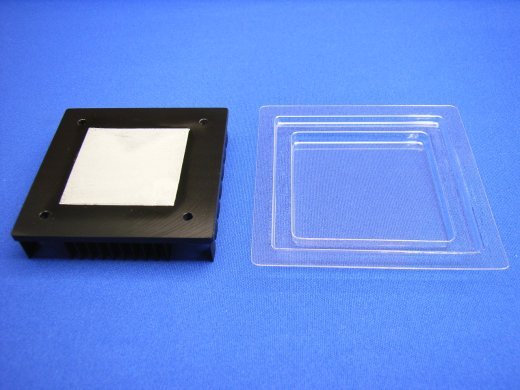

Our heat sinks are available with pre-applied thermal interface material or tape.

A variety of thermal interface materials/tapes are available and can be cut to any size.

Some thermal interface materials are available with a pull tab as shown on the heat sink on the left.

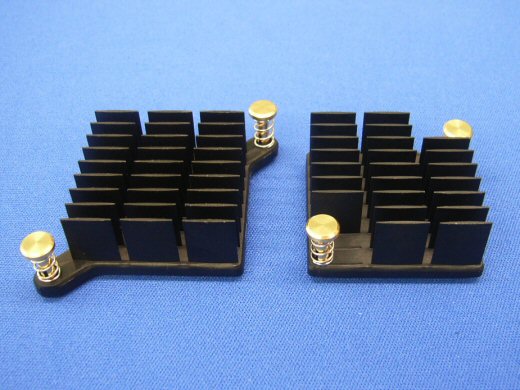

Heat sink is attached by push pins and springs. The PCB must have mounting holes.

A large combination of of push pins and springs are available to meet with almost any specification(PCB thickness, Chip size and target load).

Left:Heat sink with mounting tabs. LPDR35 - 15B

Right:Customized push pin heat sink from Standard Model LPD35 - 15B.

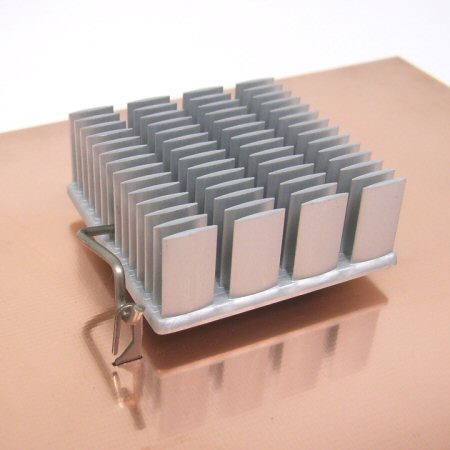

Heat sink is attached by Z-Clip. The PCB requires anchors.

Z clips and anchors can be purchased separately. Custom clips can be produced as well.

Heat Sinks can be shipped with pre-screened thermal grease. A protective cover will ship with the heat sink to prevent disturbing the grease during shipping.

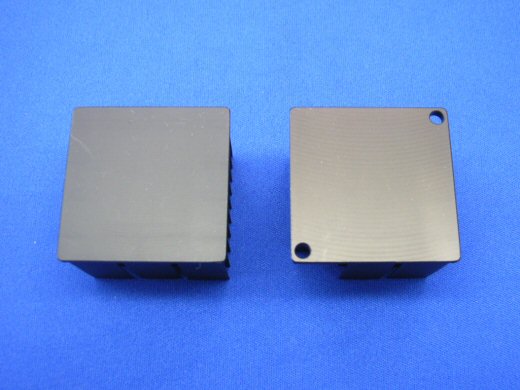

A variety of surface finishes/treatments are available.

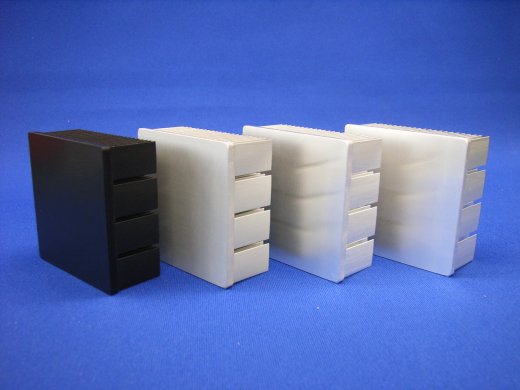

(From Left) Black Anodize, Clear Anodize, Trivalent Chromate, No Surface Finish

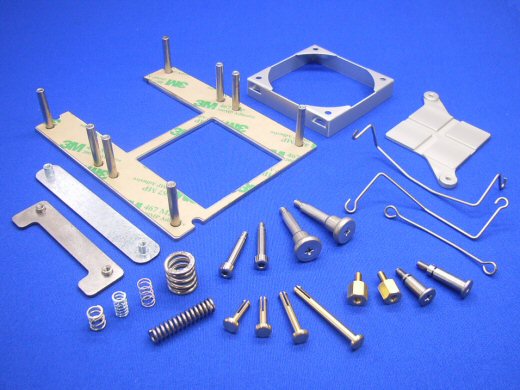

Heat Sinks can be shipped as complete assemblies with subcomponents, including fans, mounting hardware, accessories, etc...

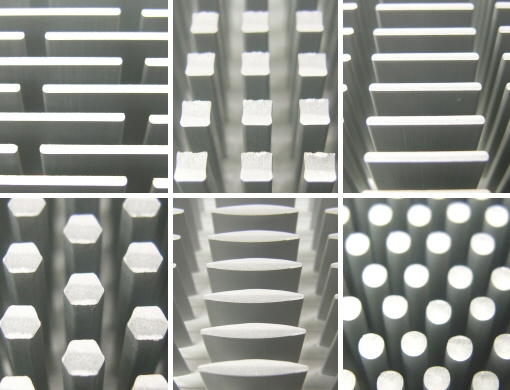

Virtually any fin shape or pattern is possible. Base size and shape is also very flexible.

With custom tooling, some feature, like prutrusion or recessed base areas can be created in the tooling, minimizing the amount of secondary machining.

Custom accessory parts, such as heat sink attachment hardware, can be quickly created.