Online Catalog

FF60

Please click here and update your password.

If you forgot your passward, please click here and update your password.

| Input Unit

| |||||||||

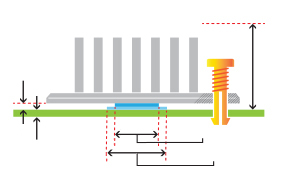

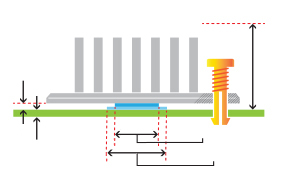

Base Thickness mm

The thermal impedance of a PCM(Phase Change Material) or Gap Filler pad depends on the pressure applied. More pressure equals lower thermal impedance and therefore better thermal performance. If the applied pressure falls below 5 psi, the use of grease, which is far less sensitive to pressure, should be considered.

Typically the spring rate for a compression spring is consistent when compressed 30% to 70% of the distance from free length to solid height. We recommend designing to this compression range.

The spring rate would be lower for compression to less than 30%, and higher for compression greater than 70%.

Also, under high compression, the spring may take a set and the load would actually be reduced.

Higher attachment loads will result in better performance from the thermal interface material. However the device must not be stressed beyond its maximum allowable load, care must be taken to avoid excessive warpage of the PCB. Please review the mechanical specifications of your device. Click "Show All Result", and find all suggested combination sets meet above.

| Heat Sink (Height h) |

|---|

| Thermal Interface |

|---|

The thermal interface materials listed here are phase change materials (PCMs).

These PCMs are naturally tacky and will be pre-applied to the heat sink. However, PCMs may peel-off from the heat sink base when removing the release liner prior to heat sink installation. Since PCMs rely on their natural tackiness instead of an adhesive, this can happen.

In light of this, we recommend that our customers apply additional pressure to the PCMs prior to removing the protective liner to allow the PCMs to wet out on the heat sink surface (refer to instruction item #4 below).

- To order individual components, such as push pins or springs,please visit each link/page.

If heatsink customization (size, hole layout, etc...) is required, please send details.

MOQ is 1 piece, typical lead time is 1-2weeks.

Currently, we do not allow this heat sink to be customized using the online tools. However, we are happy to work with you directly in creating a customized version.

Please send your detailed request to Alpha Sales by email.

(Please include a drawing/sketch if one is available).

Please include following information:

Company name : Contact name : Country : Tel : Estimated quantity : Heat Sink part number you would like to customize : Customization details :

- BASED ON ALPHA'S STANDARD TEST PROCEDURE. REFER TO TECHNICAL INFORMATION.