News

2023/03/30

Please click here and update your password.

If you forgot your passward, please click here and update your password.

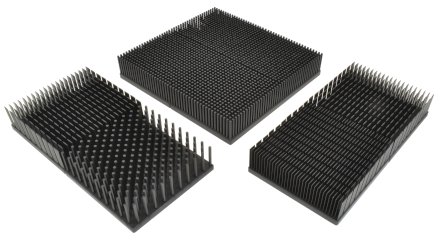

We are pleased to announce the launch of our FSW Heat Sinks. By using this process, standard heat sinks can be joined together to create larger sizes. This allows customers to obtain custom sizes with short lead times and small MOQs. In addition, by combining products with different fin patterns, optimal performance with regards to thermal resistance and pressure drop can be obtained.

Friction Stir Welding (FSW) is a high performance, energy-efficient process that joins materials by heating the surrounding material to a high temperature through friction with a rotating tool. Compared to alternate methods such as brazing or bonding, the thermal performance is superior while offering a uniform joint quality.

FSW heat sinks will retain a conical hole along the edge as part of the process. However, in testing, there was no significant performance impact thermally or mechanically.

Details of new FSW heat sinks:

| Series Name | Base heat sink | Max Length (mm) | Max Width (mm) | Overall height (mm) |

|---|---|---|---|---|

| JLP2B | LPD100 | 179.4 | 191.9 | 12-40 |

| JN-02 | N100 | 188.8 | 188.8 | |

| JUL0A | ULP100 | 179.2 | 193.8 | 12-25 |

For more information, please refer to the "FSW Heat Sink " page.

© 2023 Alpha Novatech, Inc.